|

|

Shake that paint can up good and start applying multiple light coats until the entire screen is covered on

both sides. Let that dry and do it again. Use the light to check the glare for any areas that need more paint. After you

are content with the finish and it has dried, it's time for final assembly. You will still have to wrestle the piece in, but

be glad to know that this is the last time you have to do it. As for me, I need to redo mine because I didn't quite get the

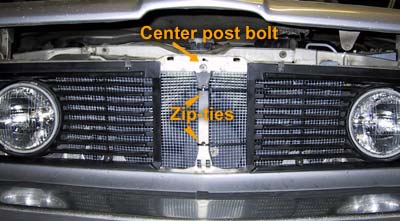

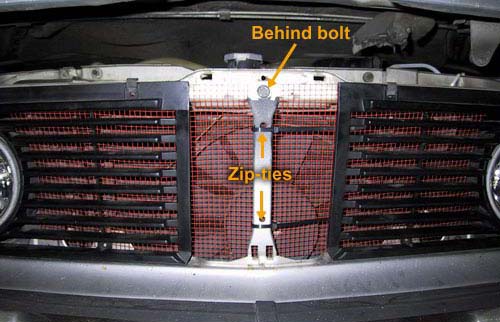

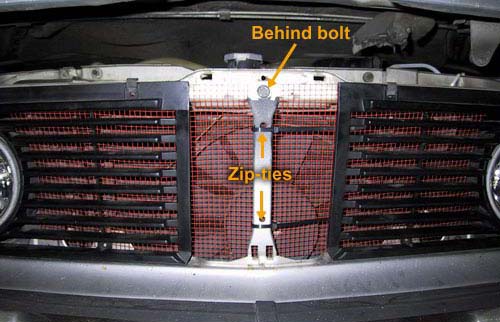

coverage I wanted. Don't forget to put the screen behind the center post bolt and zip-tie the middle pieces. Clip the

unused portions of the zip-ties off. It will take

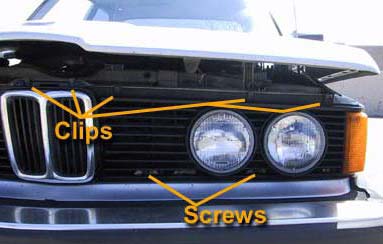

a little extra effort to clip the grille back into place but not much. Remember to put the blinker housing in using the upper

skinny end first.

|